A Visit to Rogue Creamery, Central Point, OR

I tasted my first blue cheese from Rogue Creamery, back when we lived in San Francisco, CA. There was a terrific corner cheese shop that carried it as well as having events where Rogue’s sales representatives would come in to educate and give out samples. Being new to the West Coast then, I just figured Oregon was close by and I could take a quick trip out to see their facilities. Well time passed and we moved away from CA before I ever had a chance to get out to Oregon. I loved those blue cheeses and had this draw to go see where they were made.

Now that Neil and I travel full-time, Oregon and Rogue Creamery have been on my short list of places to go. We were finally able to plan our trip about a month ago. I dug up that old business card that I had set aside back when I first met someone from Rogue Creamery, https://wineandcheesefriday.com/cheese-tasting-at-cheese-plus/, to set up an appointment. The lady in the marketing department was happy to set up a visit for me to come out and watch the cheese being made. I even found an AirBnb close to the shop so that we could walk over that day. Our main point of going to Central Point, OR was just to see Rogue Creamery so I needed to be super close!

Neil and I arrived at the shop just after they opened and we were greeted by Lincoln and Kate. They were super friendly and told us to feel free to ask any questions or let them know which samples we’d like to taste. They also gave us some recommendations of other cheese places to visit such as the Oregon Cheese Cave and Woolridge Winery who not only makes wine, but also cheese and charcuterie!

I looked longingly at the big blue cheese wheels in the case for a few minutes and then got my first taste of Rogue River Blue in quite a while. This is one of their flagship cheeses but it’s seasonal so you never know when you’ll find it. We actually snagged one of the last wedges back in that SF cheese shop and created a Wine And Cheese entry all about it.

The release of the cheese usually coincides with the Autumnal Equinox or Labor Day if you’re trying to figure out when to buy some. They embrace the local agriculture by soaking grape leaves in pear brandy and then wrapping them around the cheese. Not only does it showcase the grapes and pears of the region, it adds such a wonderful flavor to the blue cheese! This cheese has a moist and crunchy texture with some cows milk funk. If you’ve never tried it, go out and find some!

Once we had taken a quick peek around, Tim, one of their tour guides, came out to tell us all about the cheese production. The building we were in is not only the gift shop but also the cheddar production facility. Unfortunately, there was no cheddar being made that day. We found out they had been making a lot of cheddar in the last month since they were remodeling the blue cheese area. Now they’d kick up the blue cheese production and would make that for a few weeks, although their usual schedule is to alternate days between blue and cheddar cheese makes.

Since I was introduced to Rogue Creamery with their blue cheeses, I didn’t even know that they made cheddar. We found out it was a rich part of their history. Have you ever heard of “government cheese”? Well, Rogue Creamery was very involved in the program producing one million pounds of cheddar cheese back then. They even helped produce cheese for the World War II troops. They still produce their cheddars today but are more actively distributing their blue cheeses around the world. They’ve found the cheddar market to be a lot more competitive than their blue cheese niche.

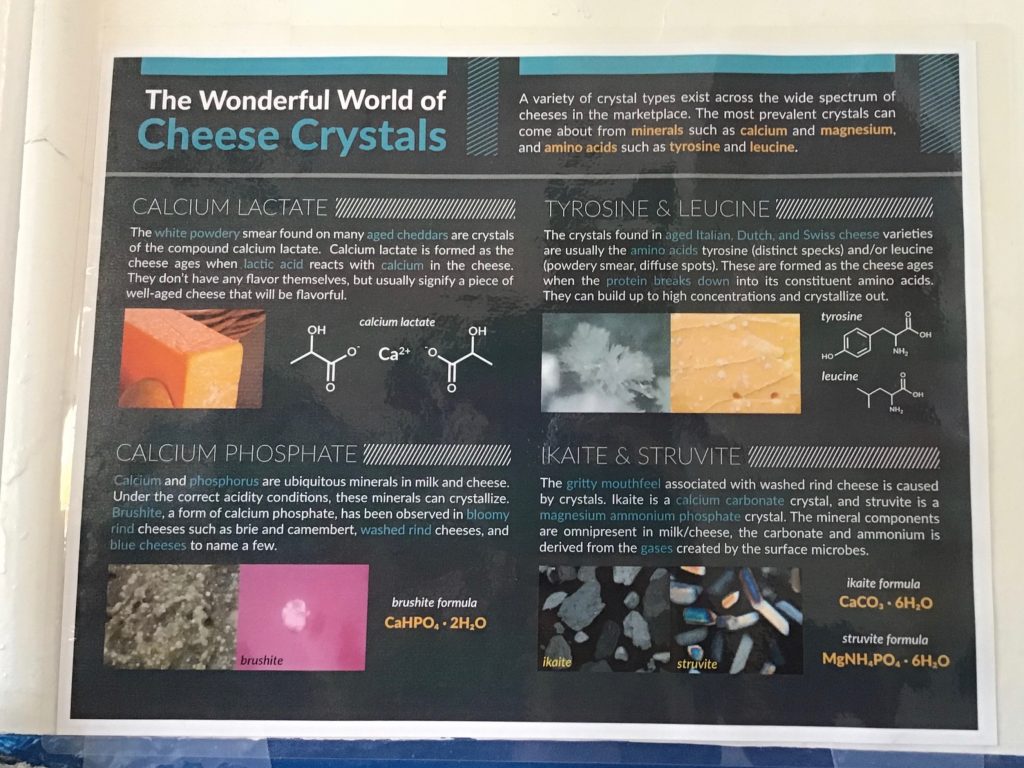

Although they weren’t actively making the cheddar cheese, we still looked through the observation window to see the equipment. Tim pointed out the cheese rakes used for moving the curds around when you drain the whey. He also let us know that the blocks of cheddar that they make are usually around 40-45 lbs. When I made cheddar at the Art of Cheese, https://wineandcheesefriday.com/cheddaring-at-the-art-of-cheese-longmont-co/, our wheel was only 2 lbs but Kate pointed out that industrial cheesemaking happens on a much larger scale than what we’d be doing that day! Those big wheels are aged between 3 months and a year and then cut and hand wrapped to be sold either in their shop or around Oregon. While we’re talking cheddar, have you ever seen a white powdery coating on the outside of your cheddar? Tim let us know that it’s only calcium lactate and that appears naturally as part of the cheddar making process.

We learned about the history of Rogue Creamery next. The Creamery began in 1930 so they’ve been making cheese for 89 years now. During their growth, they went from three employees to fifty. Tom Vella started it all with cheddars, jack cheeses, butter and cottage cheese. Does his name look familiar to you? He is also famous for Vella Cheese Company in Sonoma (https://wineandcheesefriday.com/eno/). After Tom’s death, his son Ig took over both companies. Ig became known as the Godfather of the Artisan cheese industry due to all his involvement but it was hard to promote both brands. He decided it was time to find someone who would appreciate and care for the brand as much as his family did throughout the years. He was happy to pass the legacy onto David Gremmels and Cary Bryant in the early 2000’s. They began expanding distribution and winning prestigious awards after making the process more modern and scientific.

You’ve probably heard that Rogue Creamery’s Rogue River Blue actually just won Best Cheese in the World at the World Cheese Awards in Italy. This cheese has been gaining recognition for a while now. It has won the titles of “Best in Show” by the American Cheese Society, “Best Blue Cheese in the World” by World Cheese Awards, and “1st Place Rinded Blue made from Cow’s Milk” by the American Cheese Society. But their Rogue River Blue cheese isn’t the only one with accolades. Their Smokey Blue cheese won the “Best American Cheese” by World Cheese Awards and Caveman won “1st Place Blue-veined cheese with a rind or external coating” by American Cheese Society. Their cheddars have won awards too. And it’s no wonder, because their cheeses are delicious!

We enjoyed learning so much about the company, but were happy to take a break to eat some cheese next.

Touvelle Chocolate Stout Rogue’s Mary Oregon Blue Tolman Blue Caveman Echo Mountain

We began with the cheddar cheeses and then moved into the blues. Touvelle smelled like caramel and had a creamy texture with a hint of sweetness. The Chocolate Stout had mild aromas with a slightly sharp cheddar flavor and slight cocoa. It was very flavorful! Rogue’s Mary is their rosemary cheese that smelled and tasted just like rosemary with cheddar.

Oregon Blue, their first blue, was created in 1956 based on what Tom Vella studied and learned in France about Roquefort cheese. Neil found it to be on the lighter side for a blue cheese. I could smell those “blue” aromas with smokey flavors that lingered. It was so yum!

We tasted both the Tolman Blue and Caveman and then found out that they are the same recipe with natural rinds, aged in the same conditions and use natural molds. The Tolman is just the mini format while the Caveman is the same size as the larger wheels. The Tolman seemed drier than the others and coated my tongue more. Now I know that’s because the smaller wheels have less cheese to age and get a little more dry. When I was searching for aromas with the Caveman cheese, it smelled earthy and was a little stronger than the others. Neil found it to be a super creamy cheese!

Since many of Rogue Creamery’s cheeses are made strictly from cow’s milk, we were curious to taste Echo Mountain, part goat’s milk and part cow’s milk. Neil really liked it! I could smell the milk and thought overall it had a very milky flavor.

Now that we had all these tasty cheeses in our bellies, we were ready to go see that blue cheese making facility next door.

On our way to the building Tom, the shop manager, showed us the creative ways they reused the old dairy roof as a fence and the planters made from cheesemaking equipment, both illustrating their environmental commitment. Rogue Creamery has 450 solar panels to run the plant and make some pretty tasty Grilled Cheese sandwiches, too.

We also saw the area where the tanker trucks bring the milk from their Grant’s Pass Farm. When it arrives, it’s raw milk that will be pasteurized on-site. If the milk will be used for Oregonzola it will be pumped to the facility before pasteurization since that is their only raw milk cheese. There are also quality control checks involved to be sure they can accept the 1500 gallons of milk direct from the farm.

Just like in the gift shop, the blue cheese facility has an observation window. Both areas need to follow strict health guidelines since they are food production areas but I’m happy we were still able to watch. When we came over, the guys had just started draining the whey from the large vat. The whole process of putting the curds into the forms only takes about 15 minutes to complete so we were fortunate to catch them while they were actively making the cheese. It’s a pretty labor intensive step with each person scooping up 40-lb buckets of milk and curds and dumping them into the hoops (the silver mold that shapes the cheese). Later on that day, they will flip over the hoops so that the curds can continue to drain and then about a week later these wet curds will be shaped and dry enough to pierce.

Wait, you’ve never learned about the blue cheese making process? Well it’s only slightly different than the other cheeses we’ve been telling you about lately. It begins by adding the penicillium roqueforti directly to the milk at the beginning of the process. This is the mold that grows blue in blue cheese. The other thing that happens is the cheese gets pierced. You need to create spaces for the air to get in and allow the mold to grow. The lines where you pierce, are the actual areas where you see those blue streaks form.

Their cheese cave is at the front of the blue cheese facility and was just remodeled. This is a pretty tricky scenario because these rooms have a natural mold in them that contributes to the aging process of the cheese. In order to keep that environment in place, they could only replace three of the walls. What an interesting factoid to have to consider when remodeling! This “cave” is kept at around 50 degrees with specific humidity levels and multiple blue cheese aging sections.

So now that you know about the process, the history and our tasting notes, there’s only one thing left to discuss and that’s the cows at the farm. Their farm is located in Grant’s Pass which is about 45 minutes from the creamery. At the farm you’ll find around 100 cows that include mainly holstein and brown Swiss but there are a few Jersey cows too since their milk has such a high butterfat content. Their cows produce organic milk which means that the cows start roaming the pastures around 6 months of age. Happy cows make good milk!

We didn’t make it out to the farm to see the operation but we did get to learn about the robotic milking that occurs. It seems pretty cool and efficient since about 75 cows can be milked each day. The milking system can also keep track of which cows have come to be milked. Each cow has a chip in their ear that keeps count of when they enter and exit the milking area. So they can tell if a cow still needs to go in for its daily milking. Also they said there are some cows that really enjoy the process and they have recorded that those cows go into the area more than once a day. They do get a treat each time they’re milked so I guess that’s why some cows look forward to going in more often. From a quality standpoint, the robotic milking can be a lot more sanitary and controlled to get the best possible milk without having people involved. Ah memories of my former days in the pharmaceutical industry!

It would have been great to go see the cows but we did get a pretty good idea of the whole process just by hearing about it.

Wow, we took in so much information during that three hour tour but it was great to have such an inside look into a brand we really enjoy. You’ve probably already read the entry we created about the treats we took home from the gift shop that day but if not, here’s the link. Obviously we would have loved to eat more cheese but when you travel all the time there’s choices you need to make.

Thanks so much to the whole staff at Rogue Creamery who provided a great experience to us that day. And if it’s up to me, we’ll be back again to go meet your cows, and pick up a few more cheeses to enjoy. Keep up the great work and we look forward to hearing about your next award winning cheeses!

Want to learn even more about their cheesemaking process? Their website has a section complete with “step by step” directions and some pretty fun vintage images.